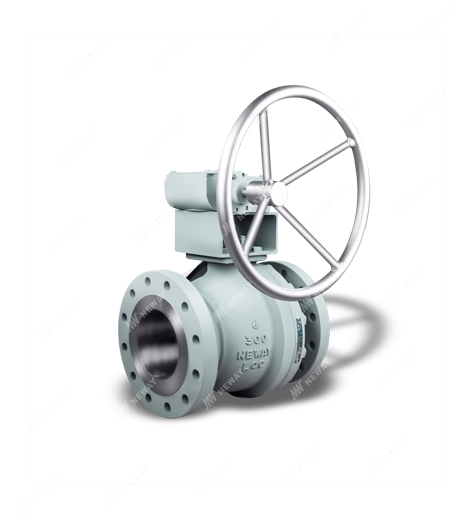

Floating ball valves play a critical role in managing the flow of fluids within a variety of industrial systems. Neway Valve, renowned for its innovative designs, offers a range of floating ball valves that are engineered to perform reliably under challenging conditions. Whether you’re working with low-pressure systems or demanding temperature fluctuations, Neway Valve’s floating ball valves ensure durability and efficient operation. This article delves into how floating ball valves work, highlighting the unique design and advantages offered by Neway Valve.

How Floating Ball Valves Operate

A floating ball valve operates based on a simple yet effective mechanism. The valve consists of a ball positioned between two seats, which is free to “float” within the valve body. When the valve is closed, the ball is pushed against one of the seats, creating a tight seal that prevents any fluid from passing through. When the valve opens, the ball moves away from the seat, allowing the fluid to flow. In Neway Valve’s designs, the floating ball is positioned in a way that enhances sealing performance and minimizes the risk of leakage. This structure allows for reliable operation, especially in low-pressure systems.

Key Features of Neway Valve’s Floating Ball Valves

Neway Valve’s floating ball valves are designed to meet stringent industry standards. These valves come in a range of configurations, including one-piece end entry and two-piece split body models. Neway Valve uses high-quality materials to ensure that each valve can withstand a wide temperature range, from -46°C to 200°C, making them suitable for diverse industrial applications. Furthermore, these valves are fire-safe, certified under API607 and API6FA, ensuring that they maintain integrity even in extreme conditions.

Applications and Benefits of Floating Ball Valves in Industrial Systems

Floating ball valves are used across a wide array of industries, including oil and gas, water treatment, and chemical processing. These valves are particularly effective in low-pressure systems (150-300LB), where reliable flow control is essential. Neway Valve’s products excel in providing safety and efficiency, particularly in situations where temperature variations and high-flow conditions are a concern. With both one-piece and two-piece split body designs available, these valves are adaptable to various system requirements.

Conclusion

Floating ball valves, such as those offered by Neway Valve, are essential components for industrial flow control systems. Their ability to offer reliable sealing, versatility, and safety make them a popular choice for low-pressure systems operating in harsh environments. With certifications like API607 and API6FA, Neway Valve’s floating ball valves meet high safety standards, ensuring long-term performance and safety in industrial applications. Whether you’re looking for a one-piece or split body valve design, Neway Valve provides a trusted solution for your flow control needs.