CNC lathe manufacturers continuously innovate to meet industrial demands for precision and efficiency. Among mainstream CNC turret lathes, most models feature either two, three, or four axes, each designed to handle specific machining tasks. Two-axis machines typically manage basic turning operations, while three-axis configurations allow for simultaneous spindle rotation and turret movements, providing greater machining flexibility. Four-axis lathes add an additional rotary axis or Y-axis movement, enabling more complex operations such as multi-sided drilling or contouring without repositioning the workpiece.

High-Speed Precision with Leichman

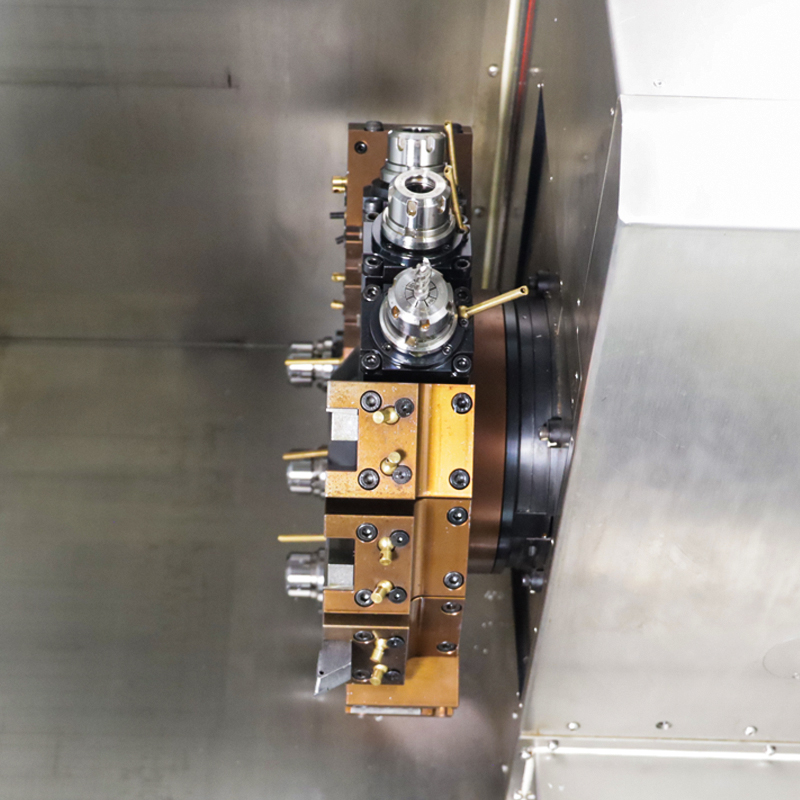

They offer the Leichman CK-52MY CNC Turning and Milling Turret Lathe 4000rpm Spindle 7.5kW Servo Motor, a machine designed for high-speed precision performance. As one of the trusted CNC lathe suppliers, this model integrates an efficient machining configuration, supporting both turning and milling in a single setup. By optimizing structural design, it reduces vibration and enhances repeatability, ensuring consistent results for various metal components. Such features make it particularly suitable for B2B clients, including factories, industrial equipment distributors, and metal processing facilities.

Differences Among Axes Configurations

Understanding the differences in axis configurations is crucial for procurement decisions. Two-axis CNC lathe suppliers often focus on standard cylindrical parts, while three-axis machines increase productivity by performing simultaneous operations. Four-axis lathes provide additional flexibility for complex geometries, reducing setup times and the risk of errors. Choosing the right axis configuration depends on the type of components, production volume, and workflow integration, which is essential for international trade and EPC projects requiring reliable and versatile machining solutions.

Conclusion: Selecting the Right CNC Turret Lathe

In summary, mainstream CNC turret lathes vary primarily by their axis count, with two, three, and four-axis machines serving different production needs. CNC lathe manufacturers such as they’s Leichman CK-52MY exemplify a high-performance solution, offering optimized structural design, high-speed operation, and efficient configuration. B2B clients such as industrial equipment agents, EPC companies, and metalworking factories benefit from selecting machines that align with their production requirements while ensuring long-term reliability and streamlined operations.