The furniture production line is the backbone of panel furniture manufacturing, and HUAHUA CNC, an ISO-certified manufacturer in Foshan’s bustling woodworking hub, has revolutionized it to prioritize labor efficiency. With 19 years of industry experience and a 45,000㎡ facility producing 8,500 machines annually, their smart furniture production line is designed to minimize manual work while maximizing output.

A Fully Automated Ecosystem

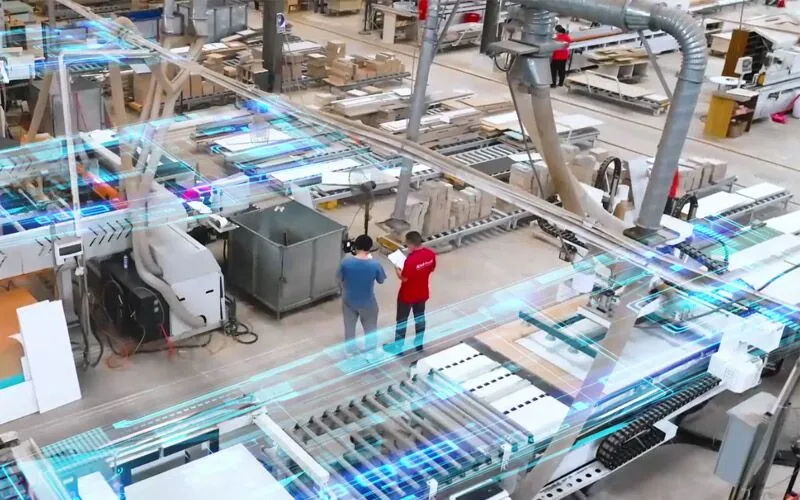

This furniture production line isn’t just a collection of machines—it’s a cohesive system. It integrates auto-labeling machines, two sets of CNC nesting units, edge banders, drilling stations, and even sorting and packaging modules, all linked by transmission devices. From the moment raw panels enter the line to the final packaging of finished parts, every step is coordinated by a central control system. This automation reduces the need for workers to handle, transport, or adjust panels manually, cutting labor requirements by a remarkable 60%. For factories struggling with rising labor costs or labor shortages, this translates to significant long-term savings.

Eliminating Human Error and Shortcuts

Manual processes often suffer from inconsistencies—workers might rush steps, misalign panels, or overlook small details. The furniture production line eliminates these risks. Each operation, from cutting to edge banding, follows preprogrammed parameters set by experienced technicians, ensuring every panel meets the same high standards. This consistency reduces rework, which in turn saves time and materials. Even complex, custom-shaped workpieces are handled seamlessly, as the line’s intelligent design streamlines transitions between different tasks.

Adaptable to Scaling Needs

Whether a factory produces 100 or 1,000 panels daily, this furniture production line adapts. Its modular design allows for adding or removing stations as demand grows, ensuring it remains efficient without overcomplicating operations. HUAHUA’s team works with clients to tailor the line to their specific output goals, making it a flexible solution for both small workshops and large-scale manufacturers.

Conclusion

HUAHUA CNC’s furniture production line stands out for its ability to automate labor-intensive tasks, cut costs, and ensure consistency. It’s more than a production tool—it’s a strategic investment for manufacturers looking to thrive in an era of rising labor expenses.