The process of selecting the best motion control solution for an industrial application requires a systematic evaluation of various factors, including the required precision, speed, torque, communication standards, and environmental conditions. The correct choice significantly impacts system performance, reliability, and cost-effectiveness. As a leader in the field, Leadshine provides a broad range of products designed to meet the diverse needs of modern industrial automation solutions. The company’s deep expertise and comprehensive product catalog—which features everything from stepper to servo technology—make it a key resource for engineers and machine builders navigating this critical selection process.

Defining Application Requirements and Constraints

The initial and most crucial step in selection is clearly defining the application’s requirements. An engineer must precisely quantify the load mass, inertia, maximum speed, acceleration/deceleration rates, and the positioning accuracy needed. For instance, a high-speed packaging machine requires fast, dynamic response, often favoring a high-performance servo system. Conversely, a simple indexing table might be satisfied with a cost-effective stepper motor system. Environmental constraints, such as temperature, dust, and vibration, must also be considered, as they influence the required enclosure rating and component ruggedness. Understanding these initial parameters is essential to narrow down the potential motion control solutions offered by manufacturers like Leadshine.

Comparing Stepper and Servo Motion Control Systems

The core decision often lies between stepper and servo technology. Stepper systems, favored for their low cost and simplicity, excel in low-speed, high-holding-torque applications where the required acceleration is moderate. Stepper motors are highly reliable for basic point-to-point positioning without the need for an external encoder. However, for demanding applications, a high-performance industrial automation solution typically requires servo technology. Servo systems, comprising a motor, drive, and highly accurate encoder feedback, provide superior dynamic performance, high torque at high speeds, and precise closed-loop control. They are ideal for rapid acceleration, complex motion profiles, and applications that cannot tolerate missed steps. Leadshine offers a full spectrum of both technologies, including innovative Closed-Loop Steppers that bridge the gap, combining the simplicity of a stepper with the position-correction capability of a servo.

Assessing Connectivity and Integration with Fieldbus

In today’s interconnected manufacturing environment, the chosen motion control solution must communicate seamlessly with the plant-level controller (PLC or IPC). This highlights the importance of Fieldbus Products. Engineers must select components compatible with the machine’s preferred industrial communication protocol, such as EtherCAT, EtherNet/IP, CANopen, or Modbus RTU. Fieldbus integration drastically simplifies wiring, reduces commissioning time, and enhances diagnostic capabilities, which are vital for complex motion control systems. A supplier like Leadshine ensures their drive and control products, including the dual-axis EtherCAT stepper drives, are engineered for high-speed, real-time communication, a non-negotiable feature for highly synchronized industrial automation solutions like CNC laser cutters or multi-axis logistics equipment.

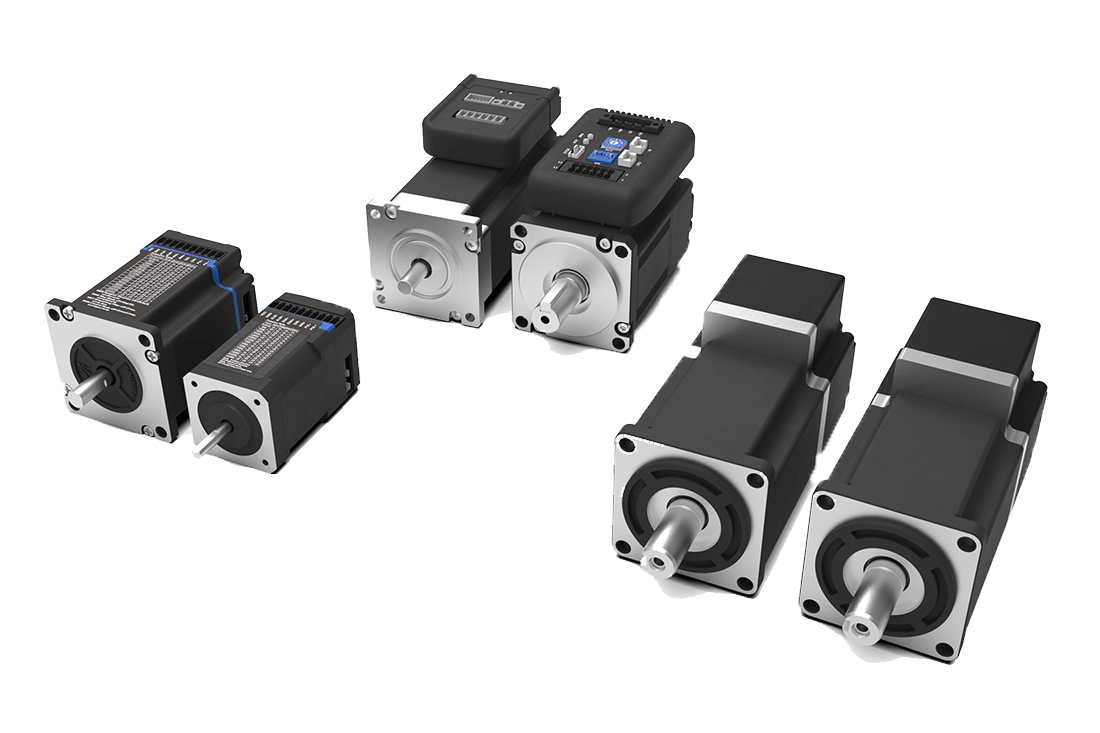

Leveraging Leadshine’s Integrated and Advanced Components

For machine builders looking to simplify design and reduce footprint, Integrated Motors offer a compelling option. These motors combine the motor, drive, and controller into a single compact unit. This design philosophy is one of the advanced motion control solutions provided by Leadshine. Furthermore, for robotic applications, the availability of specialized Robot Components, such as frameless motors and integrated joint modules, must be factored in. These high-power-density components are crucial for articulated arms and dexterity, enabling complex kinematics. The presence of such specialized componentry in the manufacturer’s lineup indicates a comprehensive provider, capable of supporting both standard and highly customized machine designs.

Considering Total Cost of Ownership and Support

While initial component price is a factor, the selection process must account for the total cost of ownership (TCO). This includes installation cost, energy consumption, maintenance requirements, and the availability of technical support. A high-quality motion control system with robust design, like those from Leadshine, may have a slightly higher upfront cost but will deliver superior reliability, reduced downtime, and lower long-term maintenance expenses. Furthermore, access to comprehensive documentation, software tools (like Motion Studio Stepper Software), and responsive global technical support is invaluable during commissioning and throughout the machine’s operational life. Ultimately, selecting the optimal motion control solution is a balance of technical specification, budget, and long-term partnership with a reliable supplier like Leadshine.