The rapid growth of the electric vehicle industry and renewable energy solutions has significantly increased demand for lithium-ion batteries. This rising need drives developments in battery manufacturing, particularly in the assembly lines dedicated to producing these essential components. Understanding the applications of lithium battery assembly lines is crucial for businesses looking to optimize their production processes and improve efficiency.

Automotive Industry Transformations

One of the primary applications of lithium battery assembly lines is in the automotive sector. As manufacturers shift towards electric vehicles (EVs), they require efficient and reliable lithium-ion battery production equipment to meet the growing demand. These assembly lines enable streamlined operations, allowing automotive companies to produce high-capacity battery packs that are increasingly vital for the performance and range of EVs.

Consumer Electronics Advancements

Lithium battery assembly lines are also pivotal in the consumer electronics market. The proliferation of smartphones, tablets, and laptops necessitates advanced battery manufacturing techniques for creating compact and lightweight power sources. High-quality assembly lines equipped with sophisticated machinery ensure that lithium-ion batteries are both efficient and durable, meeting the rigorous demands of modern electronics.

Renewable Energy Storage Solutions

Another critical application for these assembly lines is in renewable energy storage systems. With the rise of solar and wind energy products, the need for large-scale battery storage solutions that can efficiently capture and store energy has surged. Lithium-ion batteries, produced through specialized assembly lines, play a vital role in enhancing the reliability and effectiveness of these renewable energy systems.

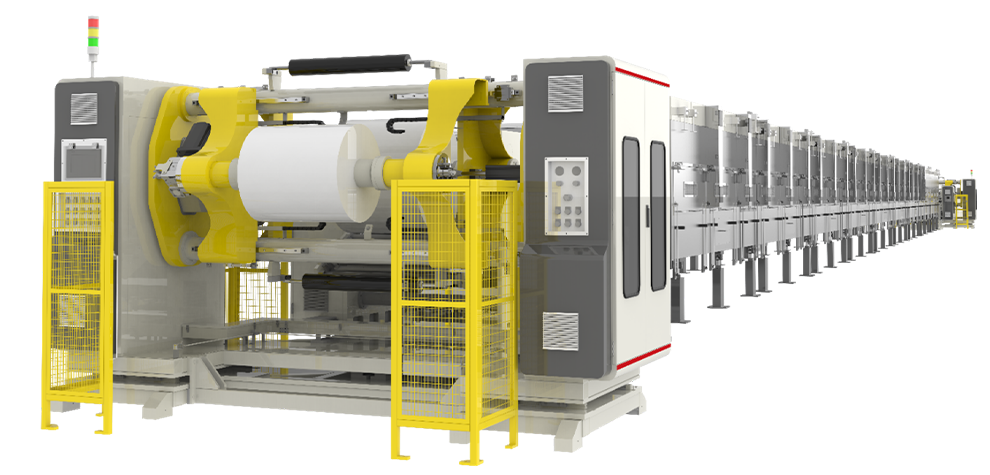

Elevating Battery Manufacturing with Yinghe

As the demand for lithium-ion batteries grows, partnering with a manufacturer like Yinghe can provide essential advantages. With an impressive production capacity of 20 billion units and over 2200 intellectual properties, Yinghe specializes in cutting-edge lithium battery production equipment. Their expertise can elevate your battery manufacturing capabilities and ensure you stay competitive in the evolving market.